Gujarat has witnessed an extraordinary surge in industrial growth in recent years. With a huge industrial landscape encompassing sectors such as textiles, chemicals, pharmaceuticals, and automobiles, the state offers a favourable environment for businesses to thrive and flourish. In this landscape of growth and opportunity, the integration of cutting-edge technologies has become imperative to drive efficiency, improve quality, and foster innovation. Among these technologies, laser scanning services in Gujarat stand out as a transformative force. This technology is revolutionizing manufacturing processes, enhancing quality control practices, and driving advancements in product design.

In keeping with this evolution, SES Digital Solutions has emerged as a leading player in the manufacturing industry, offering comprehensive laser scanning services in Gujarat. These solutions streamline manufacturing operations, facilitate precise quality control, and enhance innovative product design in Gujarat’s industrial sector. Let’s explore the transformative impact of laser scanning technology on manufacturing processes, quality control, and product design in Gujarat. First, gain a concise overview of laser scanning.

- Laser Scanning: Reshaping Manufacturing Industry

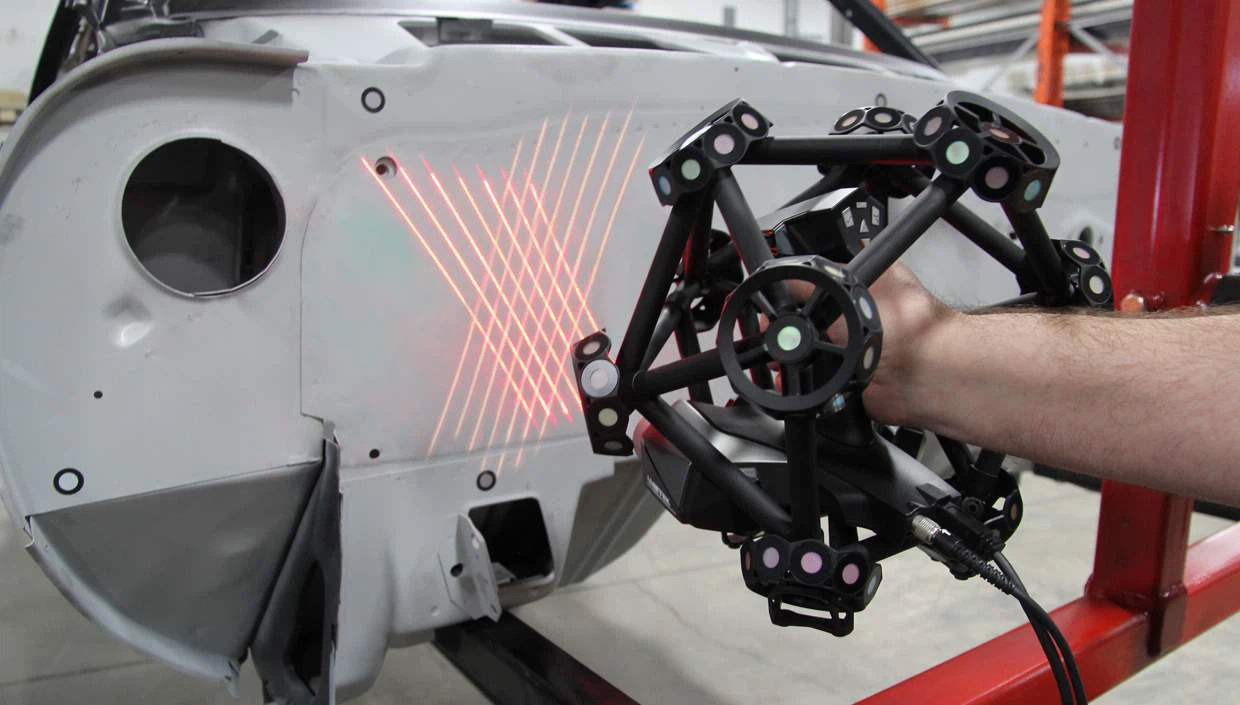

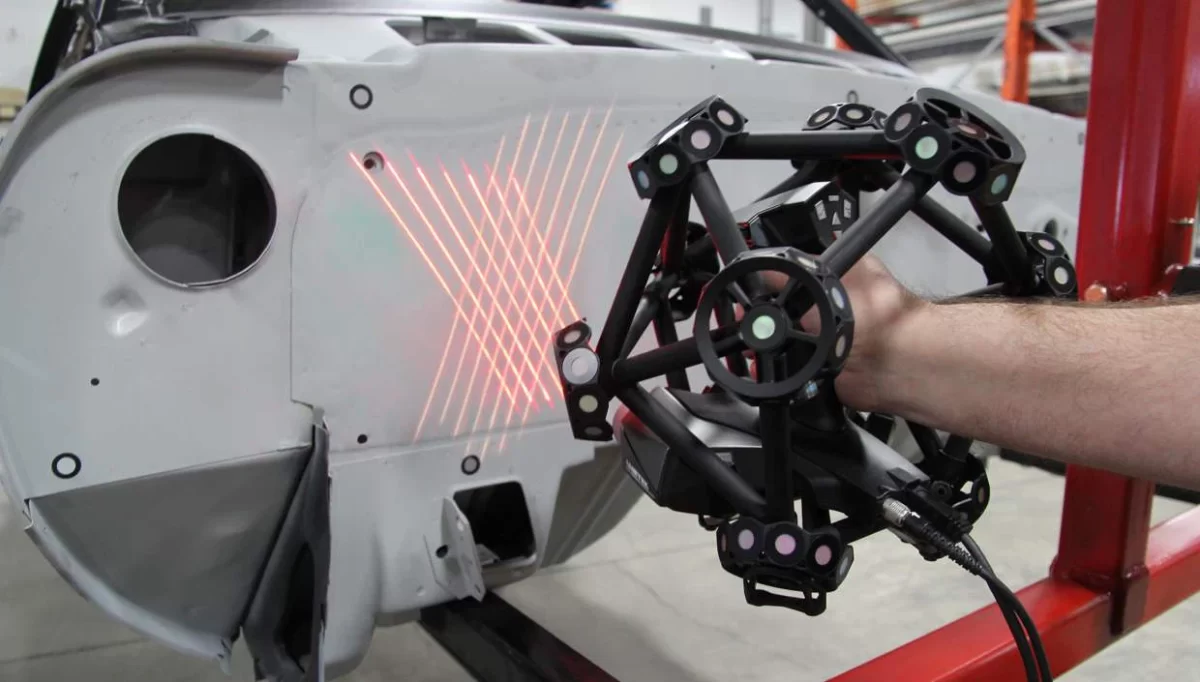

Laser scanning technology stands as the cornerstone of Gujarat’s manufacturing revival, representing a major advancement in the quest for operational excellence. Through the utilization of high-precision laser beams, laser scanning intricately captures detailed 3D representations of physical objects. Its applications span across different industries, showcasing unparalleled capabilities in capturing intricate, complex geometries, facilitating precise measurements, and producing comprehensive digital models. This technology serves as a catalyst for innovation, enabling manufacturers to achieve high levels of accuracy, efficiency, and creativity across their operations. By providing businesses with precise data and in-depth insights into their manufacturing processes, laser scanning services in Gujarat empower them to improve production workflows, minimize waste, and enhance product quality. This ultimately helps them grow and stay ahead in the competitive global market.

- The Impact of Laser Scanning On Revolutionizing Manufacturing Processes

In Gujarat’s manufacturing sector, laser scanning has redefined traditional production methods, including assembly line manufacturing, manual machining processes, and conventional quality control practices. This groundbreaking technological innovation has enabled industries incorporating chemicals, oil & gas, piping, and construction to achieve greater efficiency and productivity. Laser scanning helps them streamline operations, reduce manual labour, and enhance accuracy across various manufacturing processes. By digitizing physical assets and environments, manufacturers can optimize production workflows, minimize downtime, and reduce material waste. 3D laser scanning services in India, enable meticulous alignment, assembly, and quality assurance, benefiting industries such as automotive, aerospace, and heavy machinery. This speeds up how quickly products are introduced to the market and makes businesses more competitive. Therefore, if your business is seeking 3D laser scanning services nearby, SES Digital Solutions could be the right choice for you.

- Leveraging Laser Scanning to Fuel Innovation in Product Design

Innovation is crucial for Gujarat’s manufacturing sector, helping to constantly improve and make products and services stand out. Laser scanning technology empowers designers and engineers to push the boundaries of creativity and functionality by capturing real-world objects in intricate detail. This capability allows for rapid prototyping, iterative design processes, and customization to meet evolving market demands. From consumer electronics to medical devices, Gujarat’s manufacturers leverage laser scanning solutions to stay ahead of the curve and deliver state-of-the-art solutions to their customers. This technology enables them to explore new design possibilities, test innovative concepts, and refine products with greater precision. This further helps drive innovation and competitiveness in the industry.

- Role of Laser Scanning in Enhancing Quality Control Measures

In Gujarat’s manufacturing ecosystem, where precision and reliability are essential, maintaining quality control is crucial. Laser scanning plays a crucial role in this aspect by simplifying comprehensive inspections, dimensional analysis, and defect detection. With their ability to capture minute details and deviations with exceptional accuracy, laser scanning services in Gujarat ensure compliance with stringent quality standards, minimize the risk of defects, and foster consumer trust. This innovation enables manufacturers to uphold their commitment to delivering high-quality products consistently.

- SES Digital Solutions: Leading the Charge

In Gujarat’s thriving manufacturing landscape, SES Digital Solutions is evolving as a leading technological partner with a proven track record and deep expertise in laser scanning technology. They offer customized laser scanning solutions to address the unique needs of businesses across different industries. Whether you need laser scanning for construction or laser scanning for piping, their comprehensive services offer everything from equipment provision and data acquisition to analysis, reporting, and ongoing support. By partnering with SES Digital Solutions, manufacturing industries in Gujarat gain access to state-of-the-art laser scanning technology, backed by a team of skilled professionals committed to delivering exceptional results.

Conclusion

Laser scanning technology helps businesses unveil new possibilities and achieve unparalleled levels of efficiency, quality, and innovation. As Gujarat remains a manufacturing hub, laser scanning’s role in shaping the industry’s future will become increasingly significant. With SES Digital Solutions’ laser scanning services in Gujarat, businesses can handle challenges such as maintaining quality control standards and optimizing production workflows. They can grab the opportunities to become successful in this competitive world.