Introduction

The chemical industry is one of the most complex, high-risk sectors. It deals with hazardous materials, intricate piping networks, and strict regulatory standards. Inaccuracies can lead to safety hazards, environmental violations, or costly downtime. With its ability to capture detailed 3D data rapidly and precisely, laser scanning has emerged as a game-changer in the chemical industry. SES Digital’s laser scanning for the chemical industry is designed to meet the industry’s rigorous demands for safety, compliance, and operational efficiency.

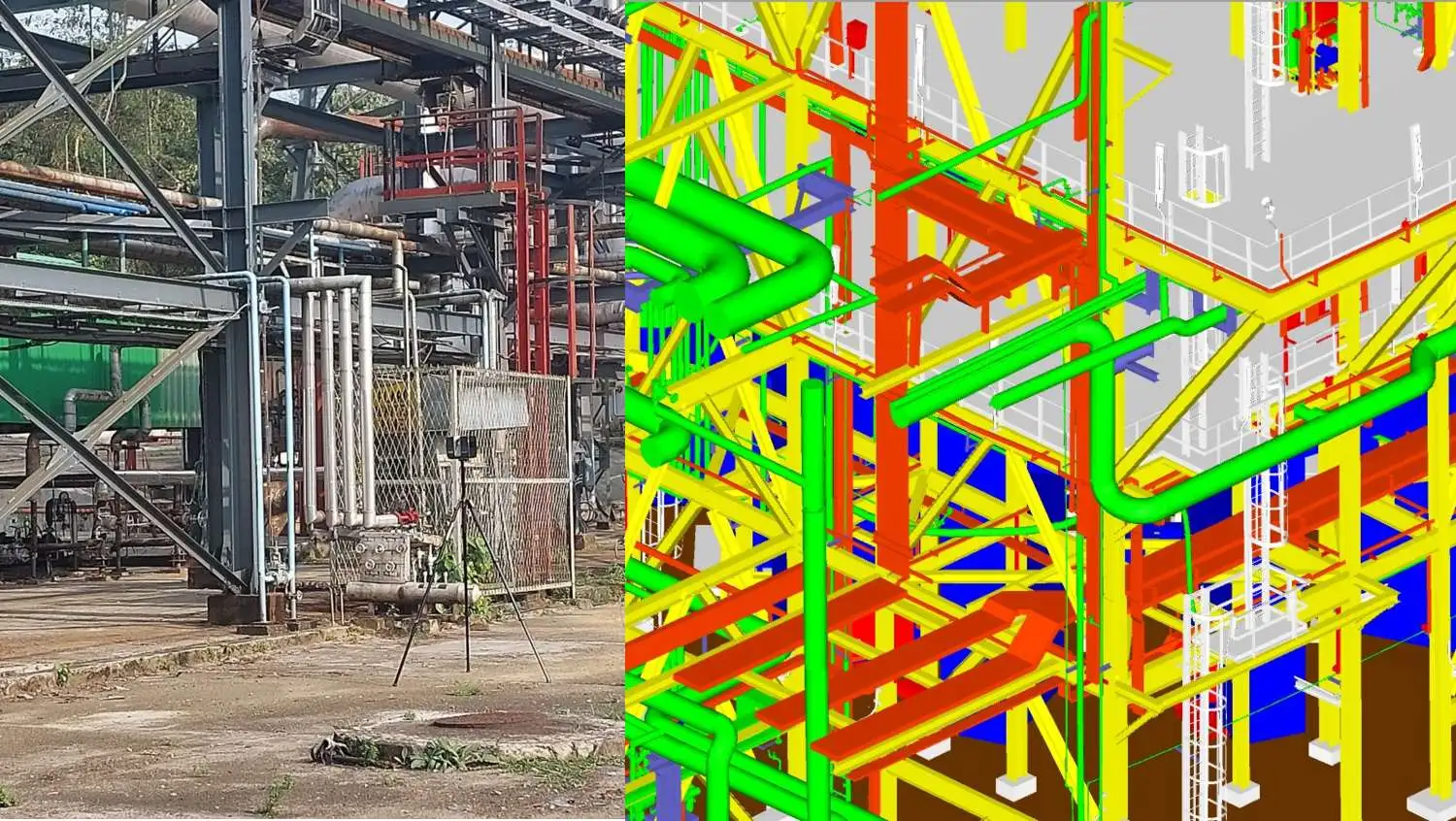

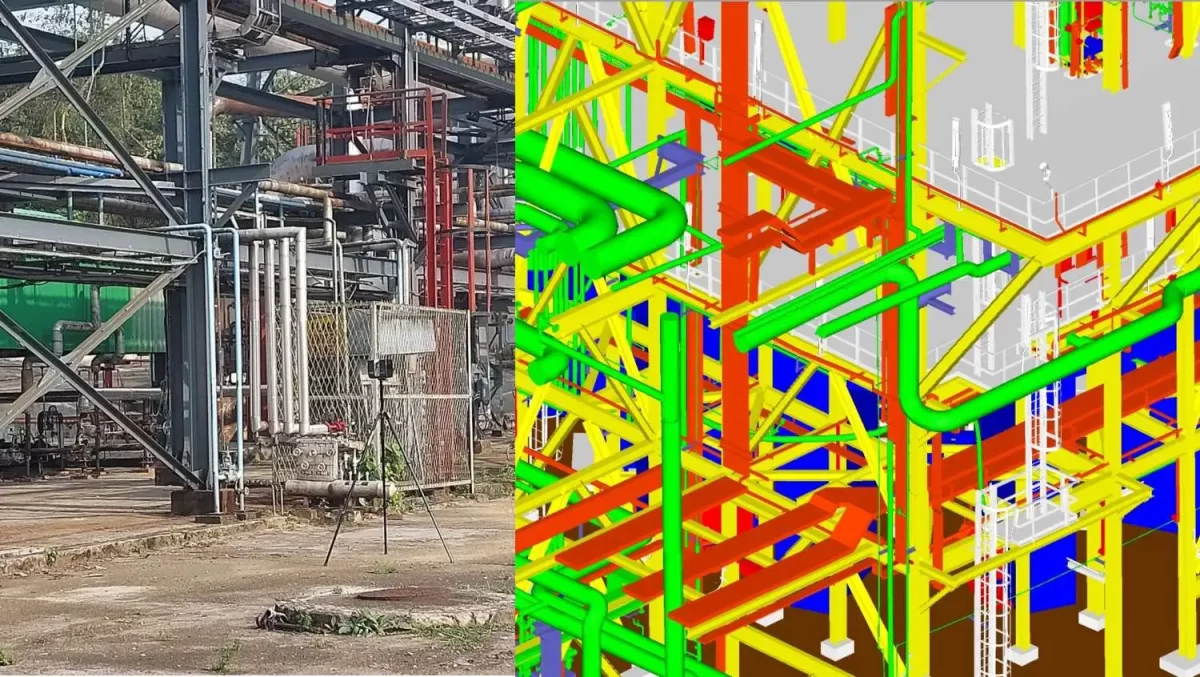

Bridging the Gap: How Laser Scanning Revolutionizes Chemical Plants

At SES Digital, our 3D laser scanning services in India provide chemical plants with an essential tool for:

- Capturing the entire facility as-is, including laser scanning for piping, heat exchangers, tanks, pumps, etc

- 3D modelling, which helps engineers visualize intricate designs, test simulations, and plan future upgrades

- Non-intrusive inspections to track changes in facility conditions over time, such as equipment wear and tear or structural deformations

Key Benefits of Laser Scanning for the Chemical Industry

- Safety and Compliance

Laser scanning technology helps identify safety hazards that are otherwise challenging to detect, such as misalignments in piping or encroachments into hazardous areas. It enables better risk assessment by offering an in-depth look at confined spaces and potentially volatile zones.

- Precision in Complex Piping Systems

Chemical plants often consist of sprawling networks of pipes, vessels, and support structures. SES Digital’s laser scanning services in Gujarat and beyond can prevent costly errors and enhance operational efficiency by identifying pipe routing, stress points, and connections correctly.

- Reduced Downtime and Costs

Traditional surveying techniques can take days or even weeks. Laser scanning significantly reduces this time by providing accurate data in a fraction of the time. Accurate information enables efficient scheduling of inspections, repairs, and upgrades, minimizing disruptions to production, all while keeping costs in check.

Advanced Applications of Laser Scanning in the Chemical Industry

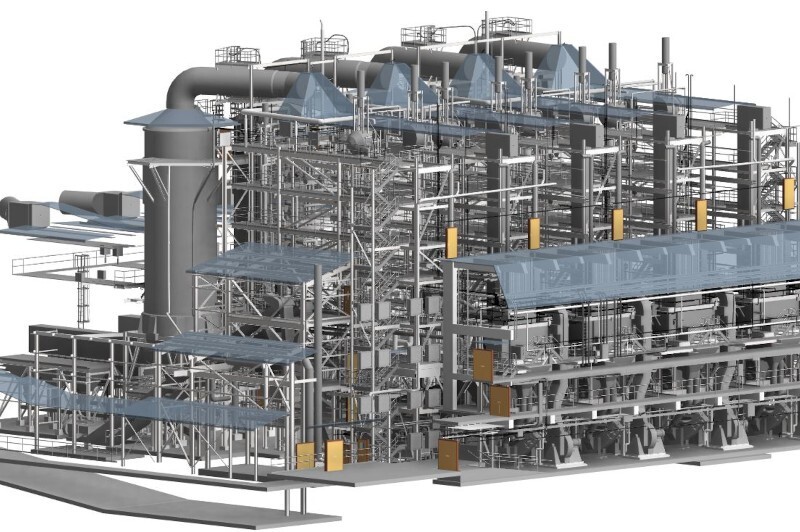

- Facility Management and Upgrades

Our 3D laser scanning services in India can create detailed 3D models of the existing facility, including the layout of utilities, reactors, and supports. It enables engineers to accurately determine the required dimensions and specifications for new equipment, ensuring a seamless integration into the existing infrastructure.

- Risk Assessment

Engineers can identify potential obstructions, clearances, and structural weaknesses by capturing the intricate details of equipment and piping systems. This information is essential for assessing the risk of fires, explosions, or chemical spills. Additionally, laser scanning for the chemical industry can be used to measure the thickness of tank walls and piping systems, helping to identify areas of corrosion or structural damage.

- Documentation and Record-Keeping

Laser scanning creates a digital twin of the facility, serving as an exact replica for future reference. Whether it’s for troubleshooting, regulatory audits, or planning new projects, this digital archive saves time and reduces the chances of errors in future projects.

Future of Laser Scanning: Sustainable Chemical Operations

3D laser scanning services in India can be employed to optimize energy consumption and reduce waste generation in chemical plants. For example, it can monitor the condition of equipment and identify potential leaks or inefficiencies that can lead to energy loss or waste generation.

AI algorithms can analyze the extensive data generated by laser scanning systems and IoT devices to identify patterns, anomalies, and potential risks. This proactive monitoring of operations optimizes processes and reduces the need for reactive repairs.

Conclusion

SES Digital’s laser scanning services for the chemical industry provide a comprehensive solution that helps meet regulatory demands, avoid downtime, and optimize operations. Partner with SES Digital today and ensure that your facility is equipped with the best tools for a safer, more efficient future.