Introduction

Piping systems are essential parts of industrial facilities that carry fluids, gases and chemicals across the oil and gas, pharmaceutical, power generation and manufacturing industries. But designing, retrofitting and maintaining these complex piping networks can be intimidating. That’s where 3D laser scanning for industrial plants helps engineers, project managers, safety experts and compliance officers fit every pipe, valve and connection perfectly into the plant.

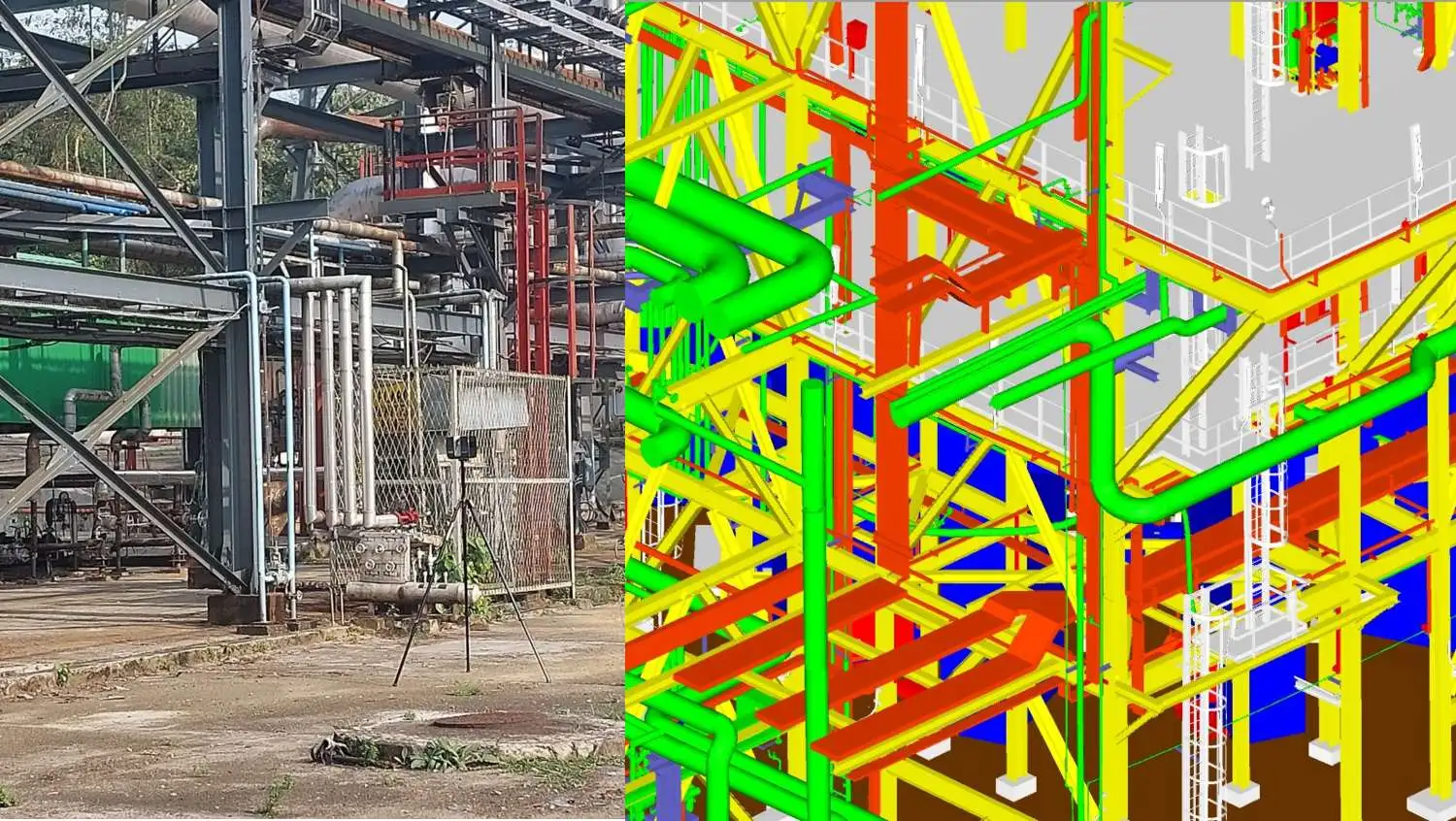

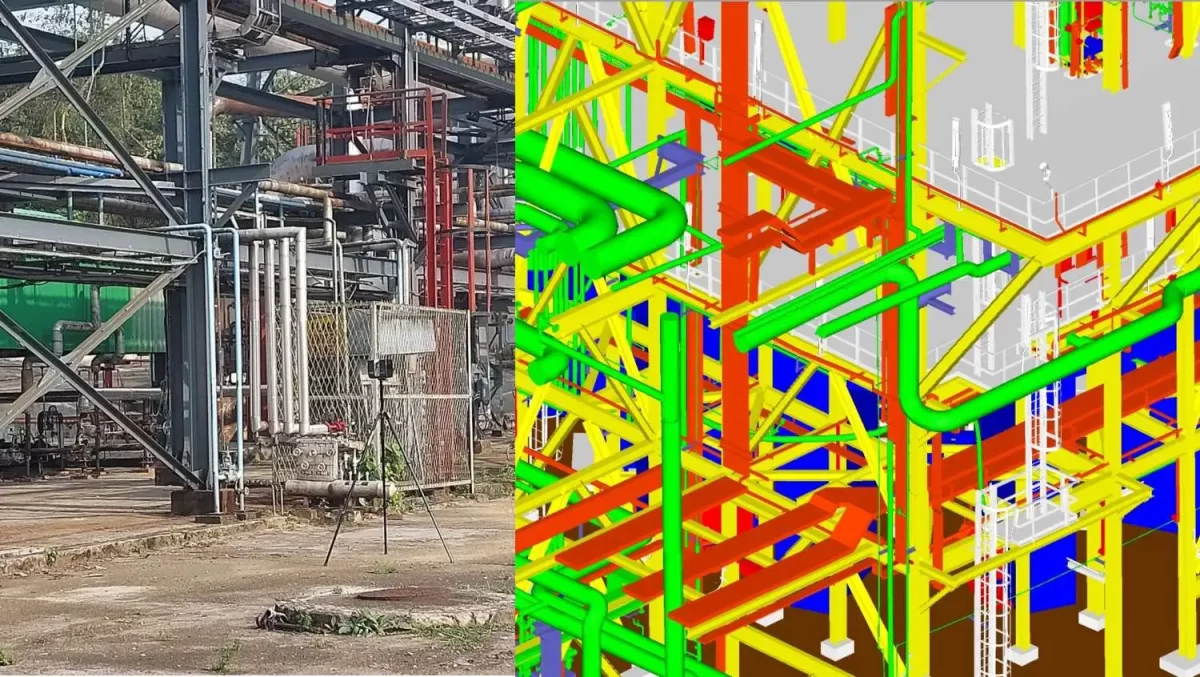

At SES Digital, we are redefining how industrial piping systems are designed and built, turning a time-consuming process into one that’s precise, innovative and agile. Whether you’re streamlining retrofits for dense piping networks in pharmaceutical plants or modernizing the infrastructure of large oil refineries, our 3D laser scanning for piping delivers results that go way beyond project milestones and deliverables.

The Hidden Hurdles: Piping Design Challenges

Developing and upholding piping layouts in industrial facilities is a tremendous job. Let’s look at some of the challenges 3D laser scanning can help with and convert them into opportunities for non-stop operation, safety and precision design:

Existing Infrastructure Complexity: Industrial facilities have pipes tangled with machinery, structural supports and electrical systems.

Legacy Systems: Refineries, steel plants and fertilizer units have aging infrastructures where blueprints are missing, incomplete or inaccurate.

Accuracy and Compliance: Small mistakes can mean big risks. Big inefficiencies. Big penalties.

How 3D Laser Scanning Is Changing the Game

As-Built Documentation

3D laser scanning for industrial plants creates real-time as-built models of piping systems down to millimeter accuracy. SES Digital’s laser scanning services allow designers, engineers and maintenance teams to plan piping maintenance and add or assess equipment without disrupting operations.

Seamless Integration of New Technologies

Indian industrial plants are adopting Industry 4.0 principles, adding IoT sensors and automation systems to their piping networks. Our 3D laser scanning for piping helps in integrating smart flow monitoring sensors into pipelines using specialized software to create compatible 3D models.

Pinpoint Precision: Piping Design Accuracy

When upgrading or expanding facilities, precise alignment of new and existing components is sacrosanct. 3D laser scanning eliminates errors, optimizes piping system performance, gets rid of pressure drops, and minimizes friction losses from the get go. For example, SES Digital’s laser scanning for the chemical industry allows engineers to design layouts where critical components like high pressure pipes, heat exchangers and reaction vessels fit seamlessly into existing systems.

Design clashes – overlapping pipes or equipment interference – are common in complex facilities. 3D models created from laser scanning allow for advanced clash detection, so you don’t have to rework during installation.

Safety First: Using 3D Laser Scanning for Industrial Plants to Lower Risk

No staff members need to go into dangerous areas and put their neck on the line for data because trained scanning technicians can remotely scan pipeline networks. Our 3D laser scanning systems are state of the art, long-range and compact so you can map confined or hazardous areas like chemical storage areas, high temp reactors or toxic gas pipes without exposing personnel to danger.

SES Digital creates 3D isometric and sectional models that map every pipe, valve and access point in high-risk areas. These models enable emergency teams to simulate evacuation routes, isolate hazards and plan rapid response.

Conclusion

In an industry where precision and safety are key to success, SES Digital’s 3D laser scanning services transform piping design by giving you actionable, high accuracy models for your application. From overlaying new piping onto dense legacy infrastructure to generating interactive models for emergency drills in hazardous chemical zones, our laser scanning for piping means every phase of your project is data driven.