Gujarat has several industrial sites that are under planning for brownfield expansion projects. Brownfield projects require handling imperfect documents, crumbling infrastructure, and hazardous materials. In these projects, uncertainty is the biggest hurdle. Any inaccuracy in site data can lead to rework, safety hazards, and getting bogged down in regulations. That’s where SES Digital’s laser scanning services come in to set the record straight with high level of precision.

We offer a variety of deliverables that can suit brownfield projects’ needs: as-built 3D models, isometric drawings, and clash detection reports. Architects, engineers, and project managers can use these insights to plan upgrades, design changes, and ensure everything is up to code. Our laser scanning for the chemical industry helps keep the potential of Gujarat’s old industrial sites intact while making them ready for tomorrow.

Why Laser Scanning is the Game-Changer for Brownfield Projects

- Accurate Documentation of Existing Conditions

For chemical plants going through expansion or retrofitting, our laser scanning services in Gujarat help engineers to accurately map complex piping networks, congested steel frameworks, and old machinery in a non-invasive manner.

- Reducing Project Risks and Unforeseen Issues

Unseen structural flaws, rusted pipelines, and undocumented modifications can throw your budget and timeline off the trail. Our engineers use the scan data to perform clash detection to give stakeholders a chance to resolve conflicts digitally before construction begins.

- Better Planning and Design

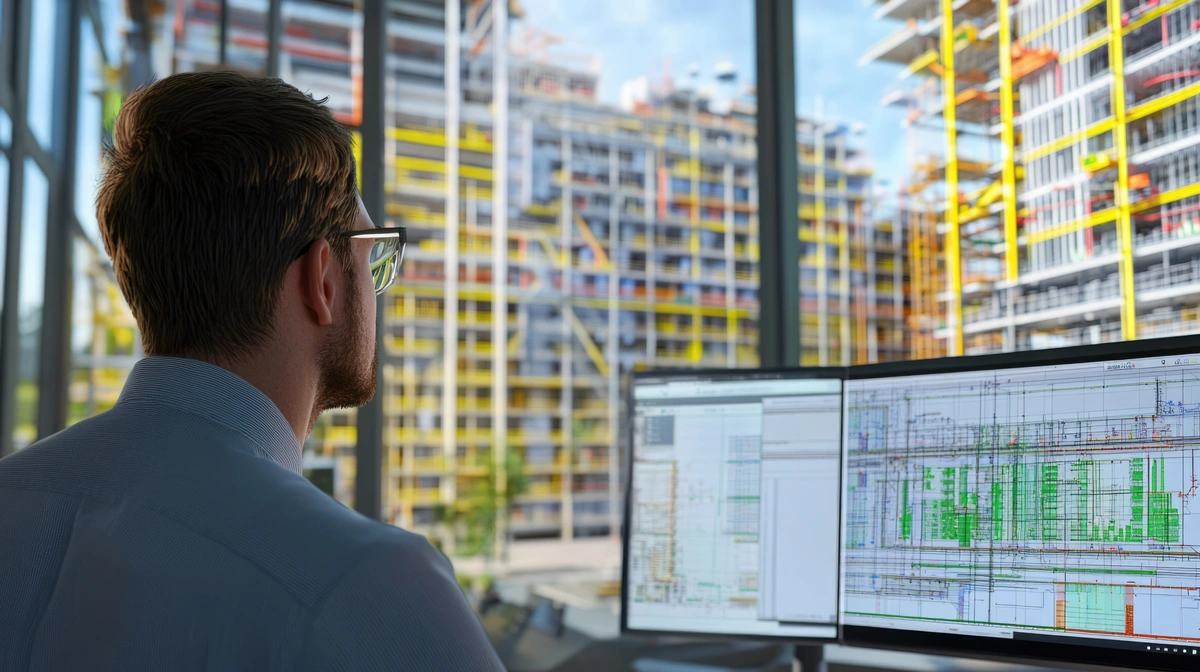

We import 3D models into review software for multi-disciplinary collaboration. Designers can see exactly how new units fit with existing systems, assess spatial constraints, validate design feasibility, and confirm the retrofit plan ticks all the safety and environmental compliance boxes.

- Time and Cost Savings

Chemical plants run on tight schedules. Even a short shutdown can trigger a domino effect of problems like expensive restarts, missed market opportunities, and contract penalties. Our non-intrusive laser scanning for the chemical industry helps keep things moving, preventing shutdowns that mess up production flow. Also, the data gathered can be reused for projects in the future, whether for repairs, additional tweaks, or compliance testing.

Applications of Laser Scanning in the Chemical Industry

SES Digital’s laser scanning for the chemical industry gives engineers the exact measurements they need to check complex piping, hazardous areas, and aging equipment. This helps us ensure proper pipe clearances to prevent pressure buildup and verify tank integrity to avoid leaks, reducing risks of equipment failure, chemical spills, and safety violations. Furthermore, digital twins created through scan data can help plant heads, and incident controllers plan safe evacuation routes and optimize emergency response plans.

Laser Scanning in Construction

In construction projects, measurement is critical for retrofitting and upgrading old buildings. Laser scanning data is used to create as-built documentation and to place new steel structures, modular units, and equipment foundations. With sustainability in focus, our laser scanning services in Gujarat help you make the most of what you’ve already got. By checking the integrity of existing structures, it allows safe reuse of materials. This cuts down on waste, reduces demolition, and helps you meet those environmental requirements with sustainable redevelopment.

Conclusion

Updating old industrial sites is all about using data to make informed choices that save time and money and ensure safety. In Gujarat’s chemical and construction industries, where downtime is a huge risk, our laser scanning services allow you to see the unseen: corrosion, misalignments, and structural weaknesses. We interpret difficult sites as clear 3D models, making planning easy, avoiding design flaws, and reducing project risk. If you want to revitalize your facility without the guesswork, we’ll help you make every decision count.