Introduction

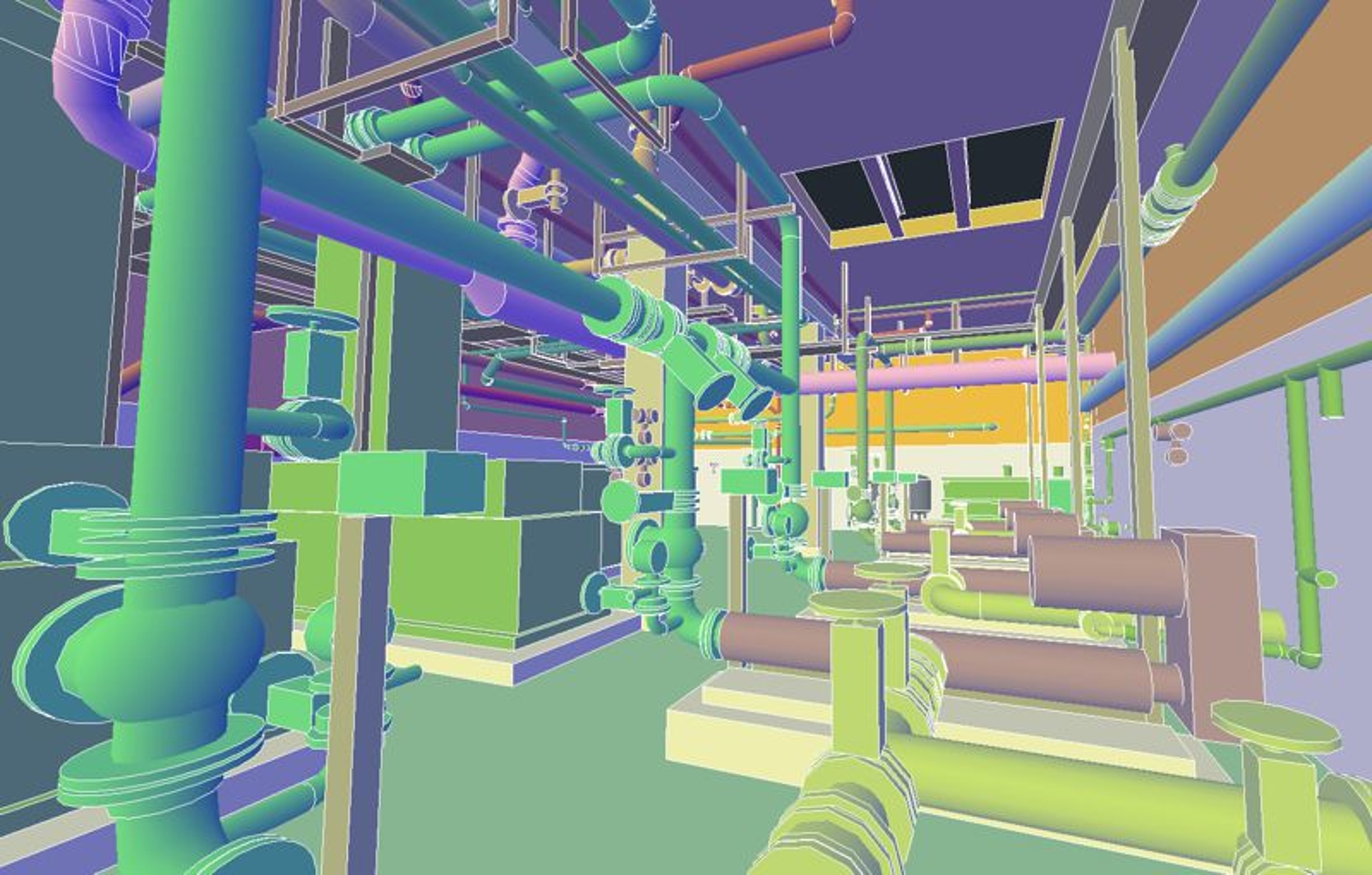

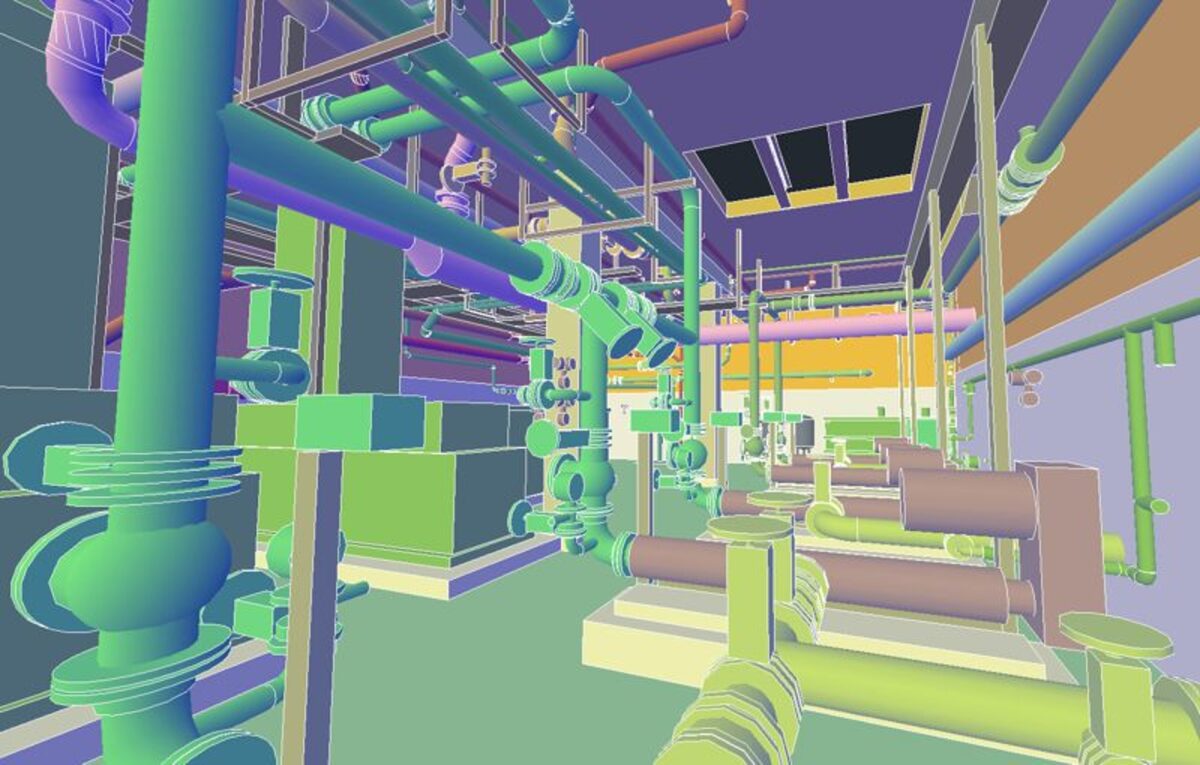

Piping systems form the backbone of countless industrial facilities, from oil refineries to chemical plants. Their intricate design, precise installation, and regular maintenance are paramount to guaranteeing safe and efficient operations. Laser scanning technology has emerged as a revolutionary solution, offering a modern approach to overcoming the hurdles of piping system management. Laser scanning for piping enables engineers and plant operators to optimize design and maintenance processes by providing highly accurate, real-time data.

SES Digital’s 3D laser scanning services in India can cover extensive areas in a short period, creating a precise digital twin of the facility. This data-rich model can be integrated with CAD software for seamless design, allowing accurate planning, clash detection, and future modifications without the need for repeated manual site visits.

Advantages of Laser Scanning for Piping Systems

- Precise Measurements for Error-Free Design and Maintenance

Unlike traditional measurement techniques, laser scanning delivers unparalleled accuracy, which may miss critical details or require multiple iterations. It ensures that every pipe, valve, and fitting is correctly aligned during installation and that any future maintenance or modification work is based on precise data.

- Minimizing Downtime During Inspections and Retrofits

Industrial plants cannot afford to halt operations for extended periods, especially for essential systems like piping. Laser scanning for the chemical industry allows engineers to perform off-site assessments, generate 3D models, and prepare for installation or maintenance without interrupting ongoing operations.

- Reducing Costs Through Accurate Planning and Fewer Errors

With a detailed 3D model in hand, engineers can run simulations to detect potential clashes and resolve spatial issues before physical work begins. This proactive approach helps prevent costly mistakes that can lead to delays, material waste, and rework.

Transformative Applications of Laser Scanning in Industrial Projects

- New Piping Installations

When installing a new piping system, the accuracy of site data is crucial for a smooth and error-free installation. Precise mapping of existing site conditions through our 3D laser scanning services in India provides a clear understanding of spatial constraints, existing infrastructure, and potential interferences.

- Retrofitting and Upgrades

SES Digital’s laser scanning services offer accurate 3D models that reflect every detail of the current piping layout, including deviations due to aging or undocumented changes. It allows engineers to design retrofits, knowing that new pipes, valves, or fittings will align perfectly with existing structures. Moreover, the generated point cloud data can be directly imported into CAD and BIM software for clash detection, structural analysis, and precise alignment verification.

- Efficient and Non-Invasive Piping Inspections

Traditionally, inspections could be invasive, requiring sections of the system to be shut down, disassembled, or otherwise disrupted. Laser scanning for piping is a non-invasive alternative that provides a complete digital model of the piping system that can be analyzed for any signs of wear, corrosion, or damage.

The Future of Piping Systems: Laser Scanning in Smart Manufacturing

One emerging trend is integrating laser scanning technology into smart manufacturing environments, where digital twins, automation, and AI-driven analytics are reshaping how industrial facilities are managed. You can combine 3D models with IoT sensors, AI algorithms, and automation systems to gain unprecedented insights into the performance of their piping systems. This data-driven approach enables real-time monitoring, predictive maintenance, and more efficient decision-making.

Conclusion

Laser scanning is transforming the way companies design, install, and maintain piping systems. SES Digital’s laser scanning for piping provides a competitive advantage by delivering highly accurate, data-rich 3D models that significantly reduce rework, minimize downtime, and optimize project costs. Whether you’re working on a new installation or conducting routine inspections, SES Digital has the knowledge and capabilities to ensure your project’s success.