Introduction

The Indian manufacturing sector is experiencing rapid expansion. This growth must be accompanied by advancements in design efficiency and precision to remain competitive on the global stage. SES Digital’s 3D laser scanning services in India capture the exact geometry of physical spaces with unparalleled detail.

The integration of laser scanning into the construction, design, and maintenance phases of manufacturing facilities is rapidly emerging as a transformative tool. SES Digital, a leading provider of 3D laser scanning services in Gujarat, empowers manufacturers with this powerful technology, enabling the creation of high-precision, data-driven manufacturing environments.

3D Laser Scanning: Capturing the Intricacy of Your Manufacturing Facility

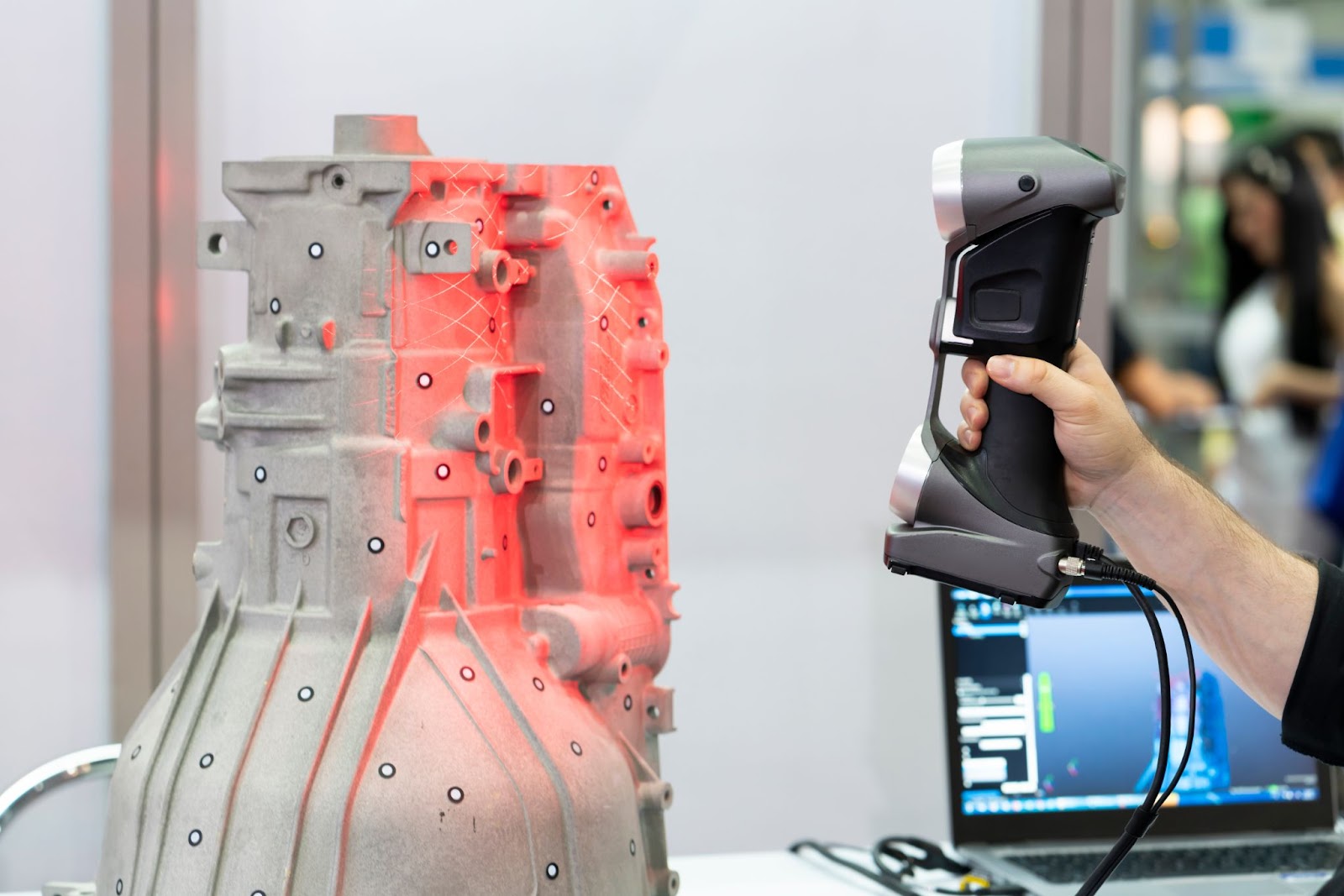

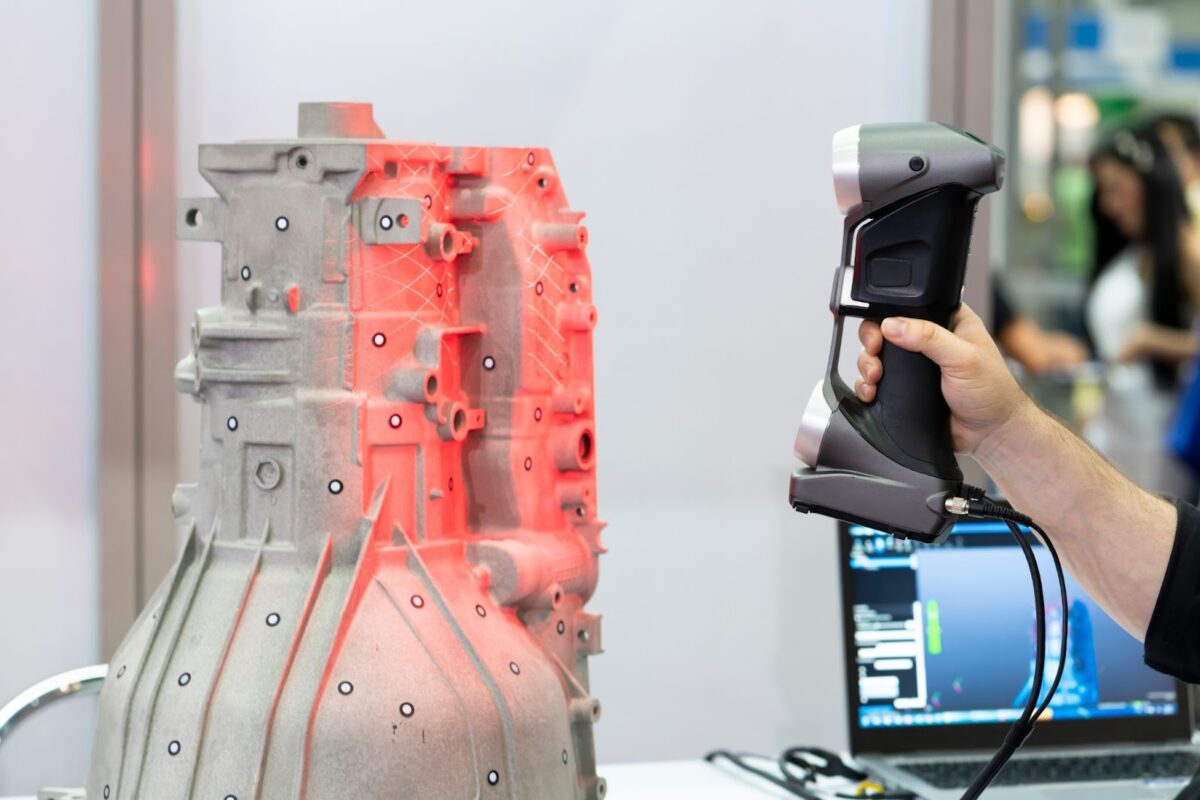

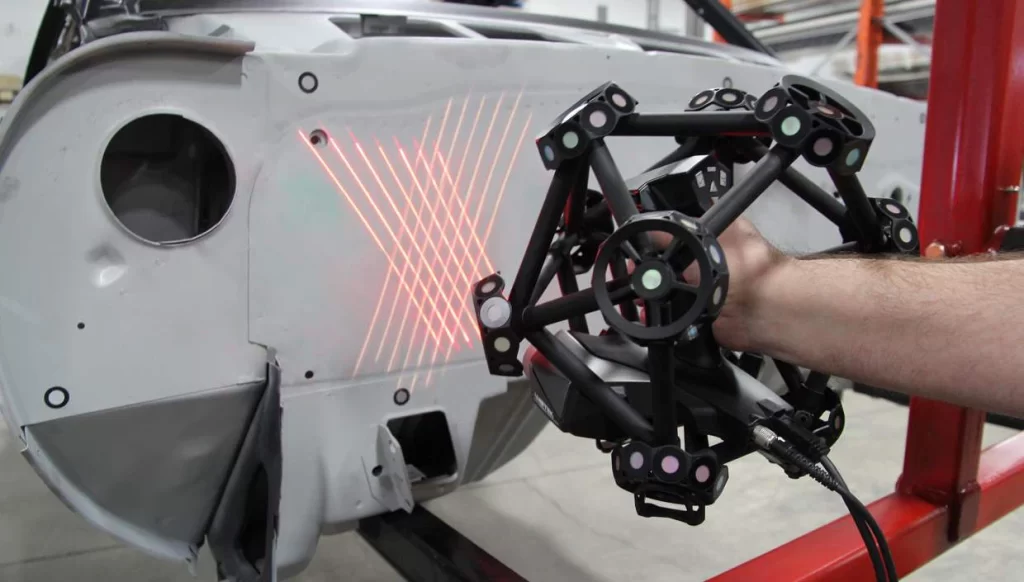

Unlike traditional design methods reliant on potentially outdated blueprints or time-consuming manual measurements, our 3D laser scanning services in India offer a comprehensive and accurate picture of your existing facility. Our state-of-the-art scanners utilize pulsed laser light to capture millions of data points, generating a meticulously detailed 3D point cloud—a virtual representation of the scanned environment. This point cloud captures intricate details such as:

- Precise dimensions of walls, floors, ceilings, beams, columns, and other structural elements

- Highly detailed scans of existing machinery, including their precise location, orientation, and footprint within the facility

- Detailed scans of ramps, doorways, and other accessibility features are crucial for ensuring compliance with safety regulations

- Laser scanning for piping captures the accuracy of overhead and underfloor piping systems, including their size, location, and connection points

Optimizing Design Decisions with Advanced Scan Data

- As-Built Modeling

Traditional design methods often rely on outdated blueprints, which may not reflect reality due to wear and tear or past modifications. SES Digital’s 3D laser scanning in Gujarat captures the existing facilities—buildings, machinery, and piping—with unparalleled accuracy. It serves as a crucial foundation for designing new production lines, integrating new equipment, or planning facility renovations.

- Collision Detection & Layout Optimization

Laser scanning for piping, equipment, and structural components allows for the precise positioning of new machinery, pipes, electrical conduits, and instrumentation within this digital space. This scan to BIM (Building Information Modeling) process facilitates collision detection, ensuring new installations seamlessly integrate with existing infrastructure, eliminating costly rework and production delays.

- Ergonomic Design & Workflow Optimization

The detailed 3D model, complemented by our advanced 3D laser scanning services in India, allows for the creation of digital mockups of workstations and entire production lines. Designers can then analyze worker movements and postures within the virtual environment, identifying areas for minimizing worker fatigue and potential injuries.

- Detailed Clearance Analysis

Laser scanning in the construction and configuration of the manufacturing unit ensures adequate clearance for equipment movement, maintenance personnel access, and material handling throughout the production floor. It minimizes the risk of operational bottlenecks and ensures smooth production flow.

The Cascading Benefits of 3D Scanning

The benefits of our 3D laser scanning services in Gujarat extend beyond the initial design phase. The captured data can be seamlessly integrated with various manufacturing processes, further propelling efficiency and quality.

- Product Design: 3D models of existing facilities can inform product design by providing precise dimensional constraints and ensuring new products integrate seamlessly into existing production lines.

- Quality Control: Digitized facility layouts facilitate automated inspection routines, enabling faster and more precise quality checks.

- Supply Chain Optimization: Sharing 3D models with suppliers streamlines communication and ensures accurate component design and fabrication.

- Preventive Maintenance Planning: Maintenance personnel can utilize the digital model to identify critical components, assess accessibility for repairs, and optimize maintenance schedules, maximizing equipment uptime.

Conclusion

SES Digital offers a comprehensive suite of 3D laser scanning services in India, specifically tailored to the needs of manufacturing facilities. Our expertise empowers you to design smarter, optimize production processes, and ultimately achieve a competitive edge in the global market.