Introduction

The persistent challenge faced by plant engineers and project managers lies in the inherent limitations of traditional measurement methods during revamping initiatives. Outdated techniques often lead to discrepancies, resulting in costly reworks and project delays. This problem underscores the crucial need for a technological leap, and SES Digital’s laser scanning services in Gujarat emerge as an effective solution to these persistent challenges.

Our laser scanning for the chemical industry captures the intricacies of piping systems, reactor vessels, and structural components, ensuring an in-depth analysis essential for seamless modifications and optimizations. Our 3D laser scanning services in India have been instrumental in the successful execution of diverse revamping projects across industries.

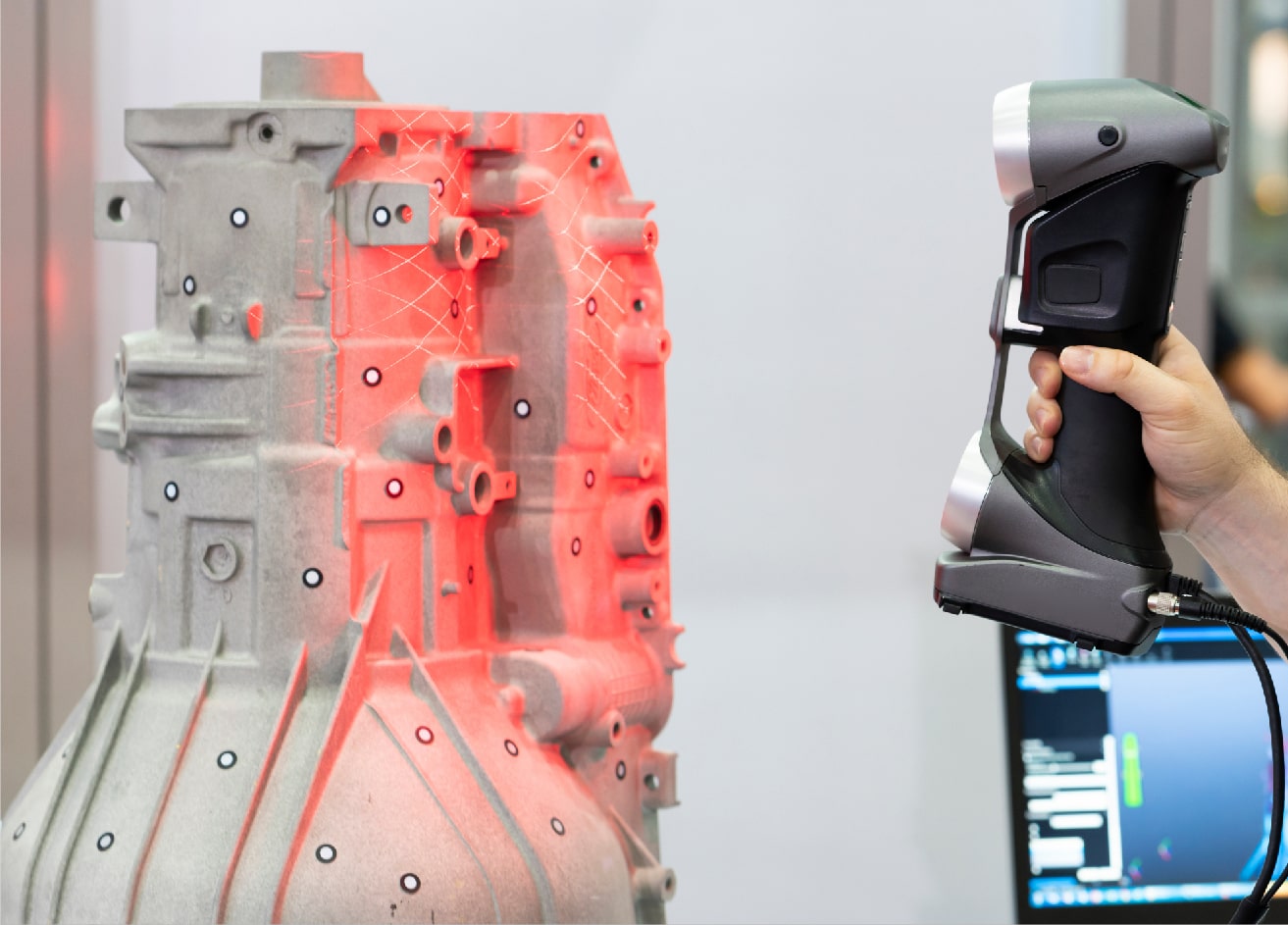

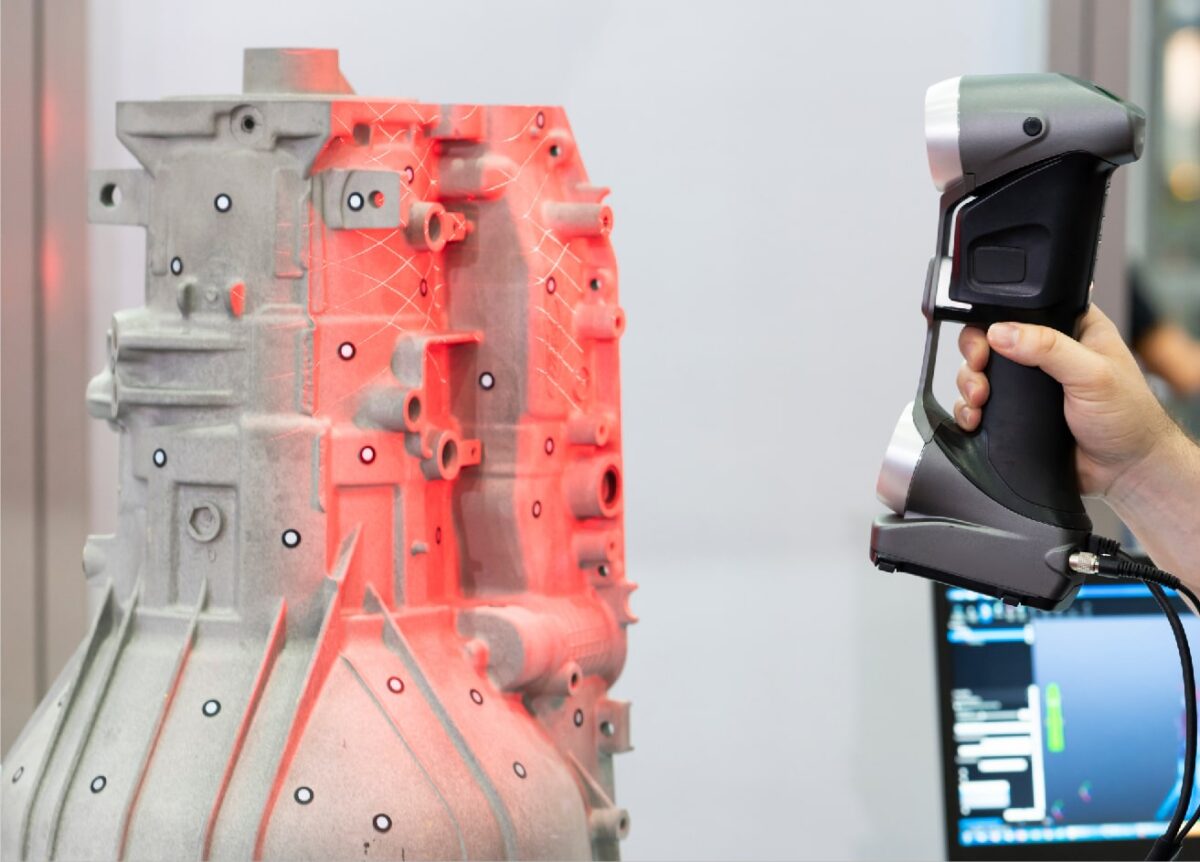

Laser Precision in Revamping Projects

SES Digital’s laser scanning services employ cutting-edge LiDAR (light detection and ranging) technology, capturing millions of data points with sub-millimetre precision.

- As-Built Documentation

Leveraging laser scanning for the chemical industry, our geospatial engineers and visualization specialists swiftly create exhaustive, as-built documentation of the existing facility. Every beam, pipe, and structural element is meticulously captured in 3D, providing engineers and project managers with an accurate representation of the current state. This comprehensive dataset becomes the canvas upon which revamping strategies are crafted, eliminating guesswork and ensuring precise modifications.

- Clash Detection and Mitigation

Clashes can be costly and potentially disastrous in the complex layout of industrial machinery and infrastructure. SES Digital’s laser scanning for piping facilitates advanced clash detection by overlaying proposed design changes onto the existing 3D model. It helps identify potential clashes between new installations and existing elements, allowing for preemptive adjustments in the design phase. This proactive approach minimizes on-site challenges and prevents costly rework during implementation.

Digital Twins: The Intelligent Blueprint for Revamping

Revamping projects demands a holistic understanding of the existing environment. SES Digital’s laser scanning services in Gujarat go beyond conventional blueprints, paving the way for creating dynamic digital twins.

- Real-Time Monitoring and Analysis

Digital twins generated through laser scanning provide a real-time representation of the facility. Our 3D laser scanning services in India allow seamless monitoring of ongoing operations, structural integrity, and environmental conditions with unprecedented granularity. This real-time insight empowers engineers to assess the impact of revamping changes on the entire system, ensuring that modifications align seamlessly with operational requirements.

- Iterative Design and Simulation

Laser scanning-derived digital twins enable engineers to engage in iterative design and simulation. Our laser scanning for the chemical industry allows engineers to test different revamping scenarios virtually to analyze their effects on the overall system performance. This iterative approach, backed by laser-scanned precision, allows for fine-tuning design elements before physical implementation, reducing the likelihood of disruptions and enhancing overall project efficiency.

Long-Term Precision Beyond Revamping

SES Digital’s commitment to precision extends far into the future, offering many technical advantages that resonate throughout the lifecycle of industrial facilities.

- Predictive Maintenance with Laser Precision

The precision captured in laser scanning data becomes a goldmine for predictive maintenance strategies. It helps us identify wear and tear on equipment, assess structural integrity, and predict potential failures before they occur. SES Digital’s laser scanning services in Gujarat lay the groundwork for a proactive maintenance approach to optimize downtime and extend the lifespan of critical assets.

- Future-Proofing with Laser-Generated Digital Archives

The detailed digital archives created through

Laser scanning serve as a dynamic foundation for future modifications, expansions, and technological integrations. A comprehensive digital dataset empowers your facility’s adaptability, allowing you to navigate evolving needs seamlessly.

Conclusion

SES Digital redefines the approach to revamping projects from sub-millimetre accuracy in capturing existing structures to creating intelligent digital twins. This cutting-edge laser scanning technology’s precision, efficiency, and enduring benefits position SES Digital as the ideal partner for forward-thinking industrial enterprises.